|

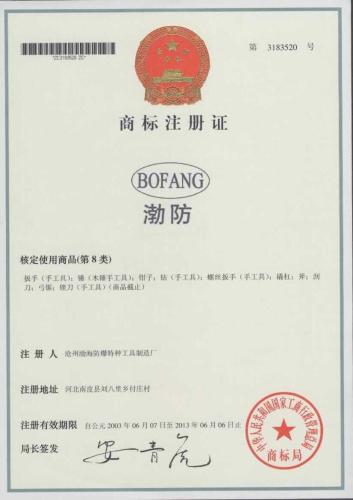

Canhzhou Bohai Safety & Special Tools Co.,Ltd

|

brass sledge hammer , sparkfree safety tools , hand tools

| Price: | 5.35~130.96 USD |

| Payment Terms: | T/T,L/C,WU |

| Special Groups: |

hand tools (7)

|

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.factory production , manufacturer price

2.Size:(kg) 0.3-8.1

3.friction and spark will not crash

4.choice material made high quality goods

Brass hammer , sledge , antispark safety tools ,hand tools

1.Data for your reference

1.Data for your reference

No. | H(g) | L(mm) | G | No. | H(g) | L(mm) | G |

1 | 450 | 310 | 610 | 11 | 3600 | 900 | 4510 |

2 | 1000 | 400 | 1300 | 12 | 4000 | 900 | 4910 |

3 | 1400 | 400 | 1700 | 13 | 4500 | 900 | 5410 |

4 | 1500 | 400 | 1800 | 14 | 5000 | 900 | 5910 |

5 | 1800 | 400 | 2100 | 15 | 5400 | 900 | 6310 |

6 | 2000 | 400 | 2300 | 16 | 6400 | 900 | 7310 |

7 | 2200 | 400 | 2500 | 17 | 7200 | 900 | 8110 |

8 | 2500 | 900 | 3410 | 18 | 8000 | 900 | 8910 |

9 | 2700 | 900 | 3610 | 19 | 8200 | 900 | 9110 |

10 | 3000 | 900 | 3910 | 20 | 9100 | 900 | 10010 |

2.Only a few companies throughout the world manufacturer of Non Sparking Safety Tools,Bo Fang non sparking safety tools is one of the leading manufacturers in this field.

3.What is a "non-sparking" tool?

"Non-sparking", "spark reduced", "spark-resistant" or "spark-proof" tools are names given to tools made of metals such as brass, bronze, Monel metal (copper-nickel alloy), copper-aluminum alloys (aluminum bronze), or copper-beryllium alloys (beryllium bronze).

Commonly used hand tools are often manufactured of steel alloys. Preferred "non-sparking" metals have less tensile strength than steels usually used to make tools. A lower tensile strength means the metal has less strength or resistance to tearing apart when stretched under test conditions. It also means that these tools are softer, wear down more quickly than ordinary steel tools, and have to be dressed more frequently.

4.Four types of products we are handling

1) Non magnetis tools(stainless steel)

2) Non sparking tools(copper alloy Al-Cu Be-Cu)

3)Special Tools (carbon steel 45#steel 40chrome)

4)Terrace Measuring Tools (general material)

Contact method

Tel :0317-8897188

Fax:8195456

Phone:15100746302

Skype number :sunnyzhao0906

Related Search

Hand Tools Hammer

Hand Tools

Tools Hand

Power Tools Rotary Hammer

Sledge Hammer

Hammer Sledge

More>>