|

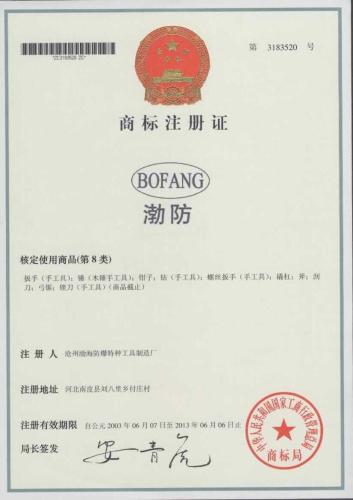

Canhzhou Bohai Safety & Special Tools Co.,Ltd

|

copper alloy striking box wrench non sparking hand tool

| Price: | 7.33~706.35 USD |

| Payment Terms: | T/T,L/C,WU |

| Special Groups: |

hand tools (7)

|

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.100% original

2.Manufacturing production , price is attrctive

3.Choice material aluminum-copper alloy ,beryllium-copper alloy

Striking Box Wrench ,copper alloy ,non sparking safety tools

Material details1.Aluminum-copper alloy explosion-proof tool HRC over 25°. Beryllium copper alloy explosion-proof tool HRC over 35 °.

2.Tensile strength of aluminum-copper alloy over 75-85kgf/mm.. Beryllium copper alloy tensile strength over 105-120kgf/mm.

3.Aluminum-copper alloy in ethylene concentration of 7.8% of space, beryllium copper alloy in the hydrogen concentration of 21% of space to ensure safety.

Pictures(any size and type is available ,show part of them below)

Welcome your inquiry !

Contact Information

The processing procedure

Al-bronze (HRC≥25°b>75-85kgf/mm² )

Be-bronze(HRC≥35°b>105-120kgf/mm²)

1) To prepare the raw material, blanking

2) Smelting

3) Pouring

4) Cut the water gap

5) Stored in the semi finished products warehouse

6) Punching

7) Through the drawbench or slotting machine

8) PE plain end and chamfering

9) Drill hole

10) Perfect the product and marking

11)If Be-bronze, need heat treatment

12) Polishing

13) Surface treatment

14)Stored in the finished products warehousePictures(any size and type is available ,show part of them below)

Welcome your inquiry !

Contact Information

Skype number :SunnyZhao0906 Tel:0317-8897188 Phone:15100746302

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Non Sparking Safety Tool

Non Sparking Tools

Non Sparking Hammer

Non Sparking Socket

Box Wrench

Copper Alloy

More>>