|

Canhzhou Bohai Safety & Special Tools Co.,Ltd

|

copper alloy double box offset wrench ,non sparking safety tools ,aluminum & beryllium

| Price: | 1.0~500.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.100% original

2.We are the manufacturer , so price is attractive

3.Absolutely anti spark in dangerous environment

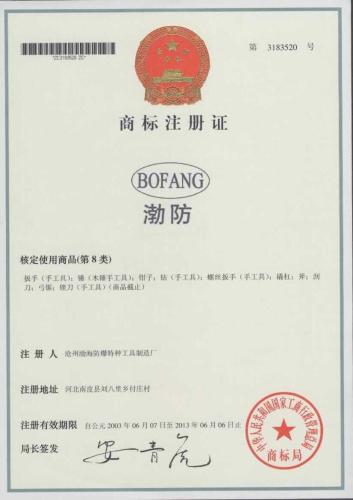

4.Chinese famous brand

copper alloy double box offset wrench ,non sparking safety tools ,aluminum & beryllium

The processing procedure

Al-bronze (HRC≥25°b>75-85kgf/mm² )

Be-bronze(HRC≥35°b>105-120kgf/mm²)

1) To prepare the raw material, blanking

2) Smelting

3) Pouring

4) Cut the water gap

5) Stored in the semi finished products warehouse

6) Punching

7) Through the drawbench or slotting machine

8) PE plain end and chamfering

9) Drill hole

10) Perfect the product and marking

11)If Be-bronze, need heat treatment

12) Polishing

13) Surface treatment

14)Stored in the finished products warehouse

Details about material

Welcome your inquiry !

Details about material

- cangzhou bohai safety &special tools co.,ltd

- Safety tool is divided into two kinds of materials: one is Be-Cu alloy, the other is the Al-Cu alloy.

- non sparking is a synthesis of precious metals, smelting, forging and tool made of the surface yellow.

- the technical indicators all reach the advanced level of similar foreign products, impact, friction, sparks an explosion not drop hammer.

- Beryllium copper alloy explosion-proof tool also has a special anti-magnetic features, in a magnetic field of the working environment can be used normally.

Contact method

Tel :0317-8897188

Fax:8195456

Phone:15100746302

Skype number :sunnyzhao0906

Welcome your inquiry !

Related Search

Non Sparking Tools

Non Sparking Safety Tool

Beryllium Copper Alloy

Beryllium Copper

Copper Beryllium

Non Sparking Hammer

More>>