|

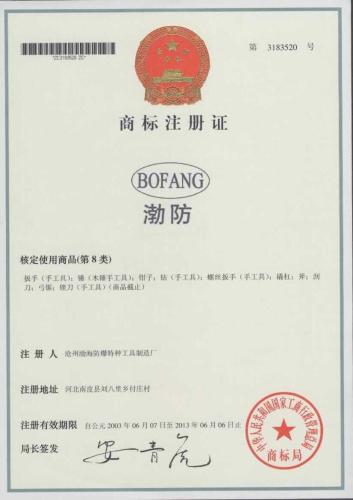

Canhzhou Bohai Safety & Special Tools Co.,Ltd

|

copper alloy hammering open ended wrench ,non sparking safety tools ,aluminum & beryllium

| Price: | 3.33~1248.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.100% original ,we are the manufacturer

2.Choice material aluminum-copper & beryllium-copper alloy

3.Fine production method :casting and forging

copper alloy striking solid wrench ,non sparking safety tools ,aluminum & beryllium

1.The processing procedure

Al-bronze (HRC≥25°b>75-85kgf/mm² )

Be-bronze(HRC≥35°b>105-120kgf/mm²)

1) To prepare the raw material, blanking

2) Smelting

3) Pouring

4) Cut the water gap

5) Stored in the semi finished products warehouse

6) Punching

7) Through the drawbench or slotting machine

8) PE plain end and chamfering

9) Drill hole

10) Perfect the product and marking

11)If Be-bronze, need heat treatment

12) Polishing

13) Surface treatment

14)Stored in the finished products warehouse

2.Production method

(1) casting

(2) forging

Solid forging die

Machinery forgings, including freedom of die forgings and precision forging

3.Quality

The products are made of choice of material so we assure you of the top quality

4.Package

Cases , wooden cases or as to your requirements . It is not only fashionable and attractive but also strong enough for long voyage

5.Company aim

Catch up with and surpass the advanced level in the world and now we are already one of the leading manufacturers in producing safety and special tools.

6.Our company produces a range of explosion-proof special magnetic tool in the industry belong to professional standards.

Name | Material | Brand | Performance | Applications |

Four Prong Fork | Copper alloy | Bo Fang | Non sparking | Gas station |

Small oil depot |

7.Contact method

Tel :0317-8897188

Fax:8195456

Phone:15100746302

Skype number :sunnyzhao0906

Welcome your order !

Welcome your order !

Related Search

Non Sparking Tools

Non Sparking Safety Tool

Beryllium Copper Alloy

Beryllium Copper

Copper Beryllium

Non Sparking Hammer

More>>